|

Overview

The KS-type high-efficiency

non-clogging and leak-free pulp pump

is a new generation of pulp pump

products developed by digesting and

absorbing advanced foreign pump

technologies, combined with the pump

requirements of domestic papermaking

and pulping enterprises. It features

significant advantages such as high

efficiency, excellent anti-clogging

performance, leak-free operation,

and convenient installation and

maintenance. It is widely used for

transporting pulp media in

papermaking and pulping enterprises.

Usage

Instructions

�� Pulp and Paper Manufacturing

�� Sugar and Starch Production

�� Chemical Raw Materials Handling

�� Industrial Wastewater Management

�� Environmental Protection Projects

�� Municipal Engineering

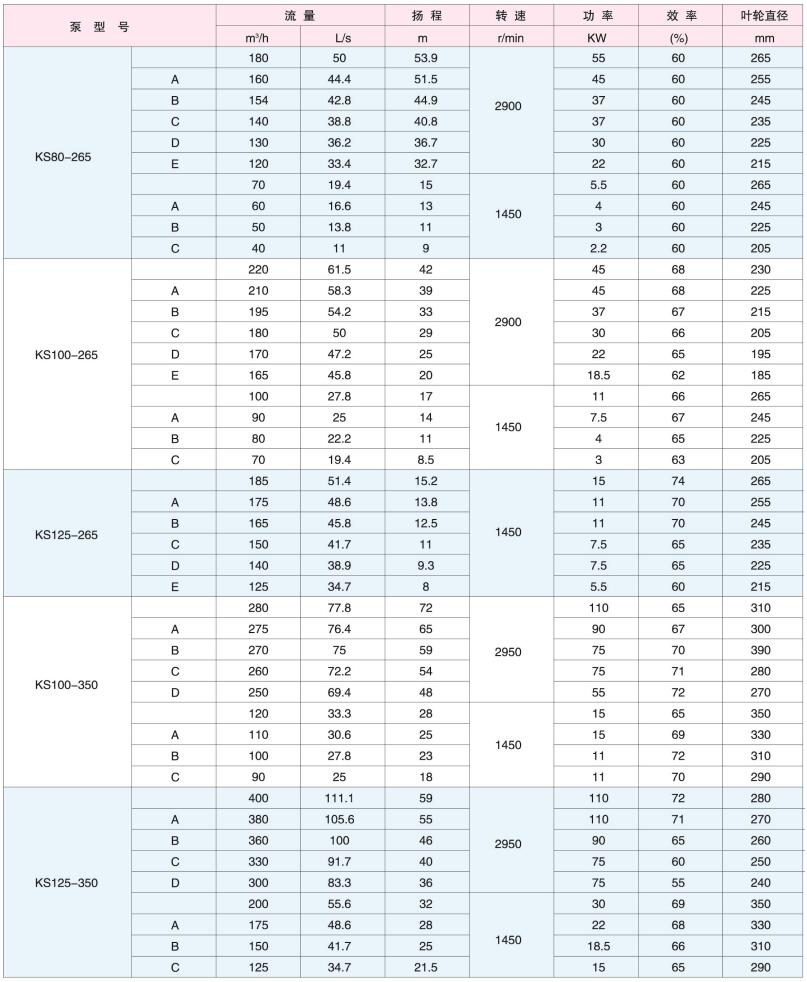

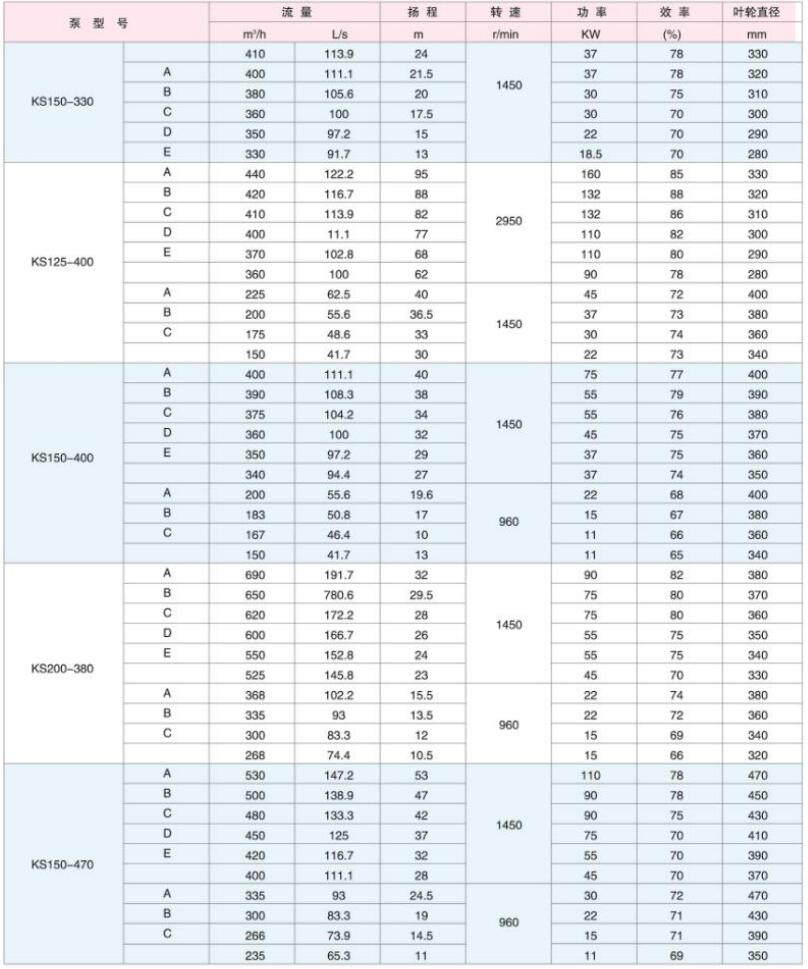

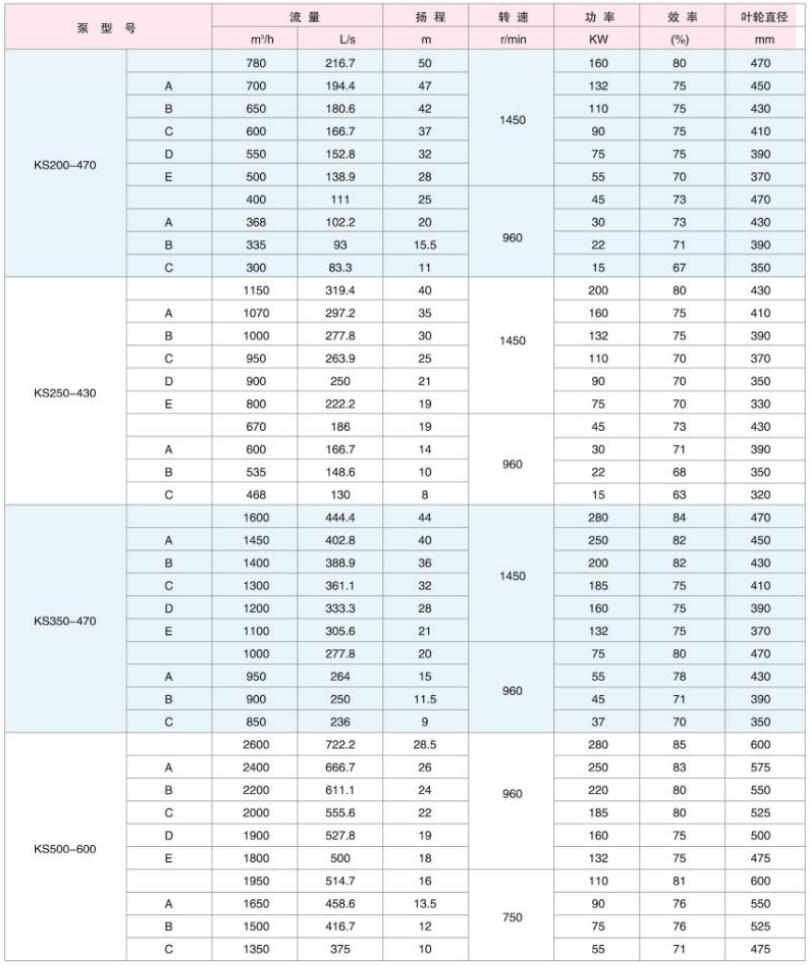

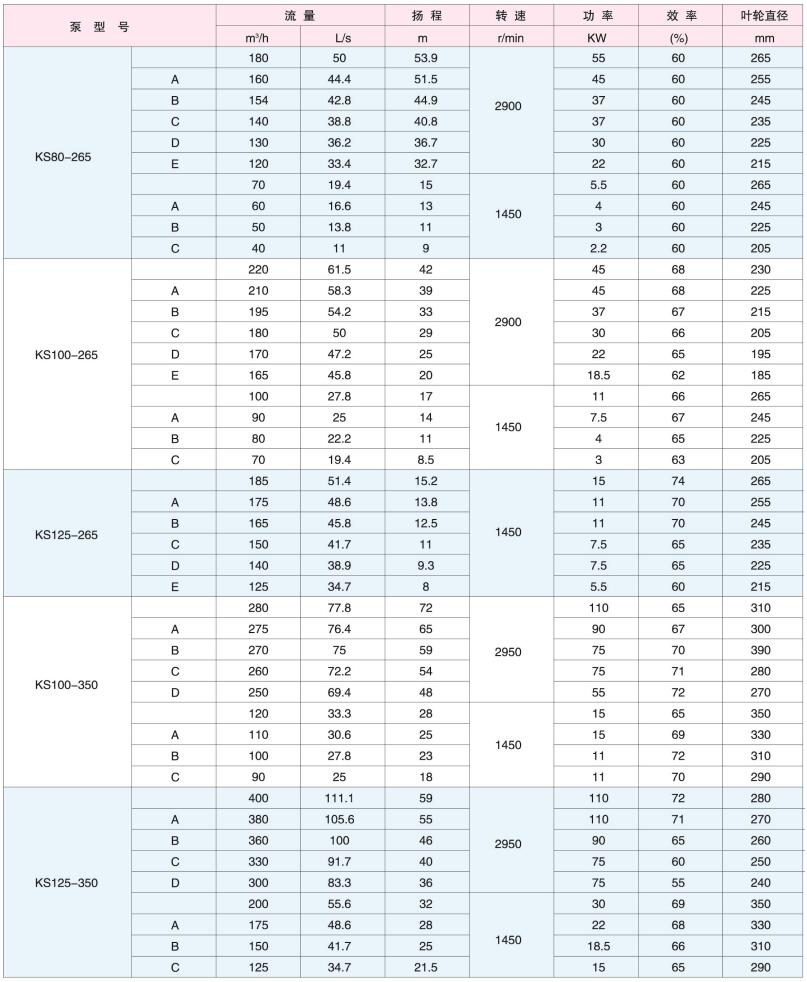

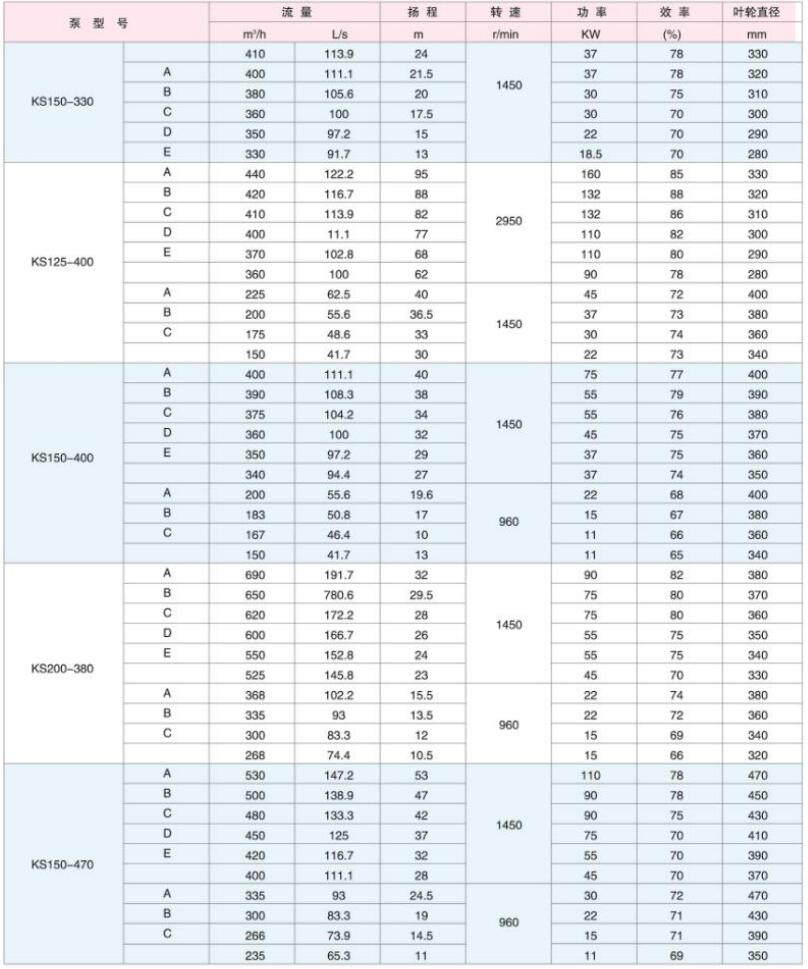

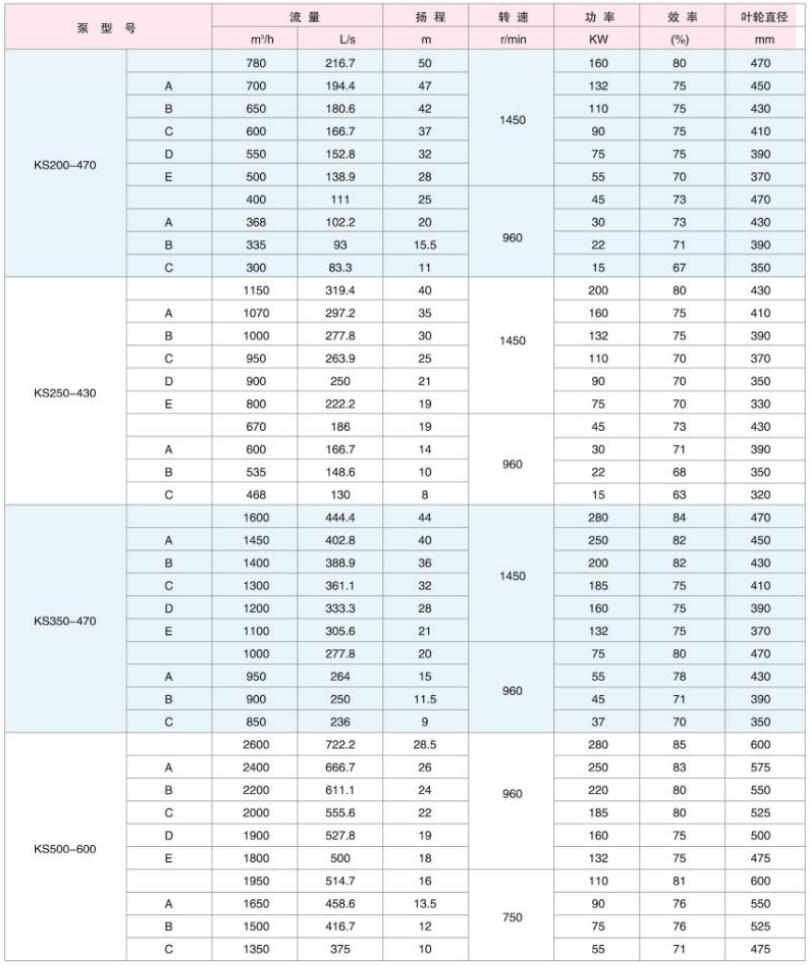

Performance Range

Flow Rate: 40�C3300 m³/h

Head: 5�C100 m

Pulp Concentration: ��6%

Operating Temperature: ��120��C

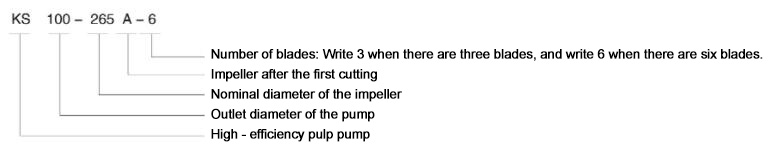

2. The

inlet and outlet flanges of the

pump are designed according to a

pressure of 1.6 MPa.

3. The

impeller adopts three - blade

(or six - blade) and is an open

- type impeller. It has high

efficiency, does not require

axial thrust compensation, is

easy to maintain, and has a low

chance of clogging.

4. The

pump shaft is supported by

imported SKF cylindrical roller

bearings for oil - lubrication,

heavy - load and anti -

friction, combined with radial

thrust ball bearings (angular

contact ball bearings). The

cylindrical roller bearings are

installed at the pump end, and

the radial thrust ball bearings

are installed face - to - face

at the drive end.

5. The

shaft seal mainly has five

types, namely standard single -

end face mechanical seal, front

- and - back arranged mechanical

seal, double mechanical seal,

packing seal, and dynamic seal.

Users can select according to

requirements and actual

operating conditions.

6. The

impeller is precision - cast by

the lost - wax method and

undergoes dynamic balance

verification.

7. The

materials include cast iron,

cast steel, ordinary stainless

steel, and duplex stainless

steel.

Performance

Parameters

|