|

Overview

The 2BE series water - ring vacuum

pumps are single - stage and single

- acting. The distribution plate and

impeller adopt optimized design.

They feature no friction surfaces,

oil - free lubrication, compact

structure, reliable operation,

convenient use and maintenance, a

wide selection range, and simple

structure with easy maintenance.

These pumps are mainly used for

pumping gas without particles. The

working medium is normal -

temperature clean water. For special

requirements, other media such as

acid and alkali can also be used as

the working fluid. The gas volume

range is 4.8 - 450m³/min, the

ultimate vacuum degree is 33hpa or

160hpa, and the efficiency is 40 -

65%. They are widely used in

industries such as power, chemical,

coal mining, papermaking, plastic

machinery, environmental protection,

medical, pharmaceutical, food, and

packaging.

1. Single - stage and single -

acting. The distribution plate and

impeller adopt optimized design,

featuring high efficiency, simple

structure and easy maintenance.

2. The flexible valve plate

automatically adjusts the exhaust

angle, enabling the pump to operate

efficiently under different suction

conditions.

3. The impeller end face adopts a

hierarchical design, reducing the

pump's sensitivity to dust in the

medium and water - quality scaling.

4. The stuffing gland is of split -

half structure, facilitating the

replacement of packing.

5. Small - sized pumps are available

with two types of shaft seals:

packing seal and mechanical seal.

6. For rotors of pumps with an

impeller diameter larger than 200mm,

a shaft sleeve is installed at the

shaft seal position to protect the

shaft from wear.

7. The bearing structure is

improved, with high axial and radial

load - bearing capacity and precise

positioning, ensuring the reliable

operation of the pump.

8. Equipped with a heat exchanger to

realize the recycling of the working

fluid, reducing water consumption

without the need for an additional

pressurization device.

9. When an anti - cavitation device

is installed, it can effectively

improve the pump's anti - cavitation

ability when operating at high

vacuum.

10. A specially - designed steam -

water separator is used for

separation, effectively reducing

resistance and noise.

11. The smooth surface of the wetted

components can effectively reduce

sedimentation and the scaling

process.

12. For pumps of specifications 30 -

70, the pump body and side cover are

connected by flanges, ensuring

overall rigidity and vibration

resistance.

13. Wide suction range. When

equipped with a primary ejector, the

suction pressure can be lower than

33hpa.

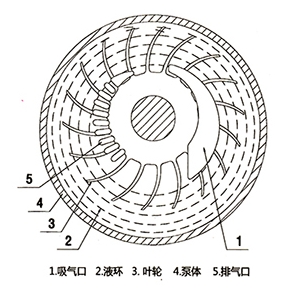

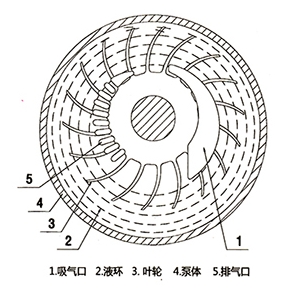

Working Principle

he impeller is eccentrically

installed in the pump body. Before

starting, a certain height of water

is injected into the pump. When the

impeller rotates, the water forms a

rotating water - ring on the inner

wall of the pump body under the

action of centrifugal force. The two

end - faces of the blades and the

plane of the distributor form a

sealed cavity. During the first half

of the rotation (when passing the

suction port), the volume of the

sealed cavity gradually expands, and

gas is sucked in through the suction

port. During the second half of the

rotation (when passing the exhaust

port), the volume of the sealed

cavity gradually shrinks, and gas is

discharged through the exhaust port.

In order to maintain a constant

water - ring, water must be

continuously supplied to the pump

during operation.

Drive Modes

Direct connection with the

motor, belt drive, and reduction

gearbox.

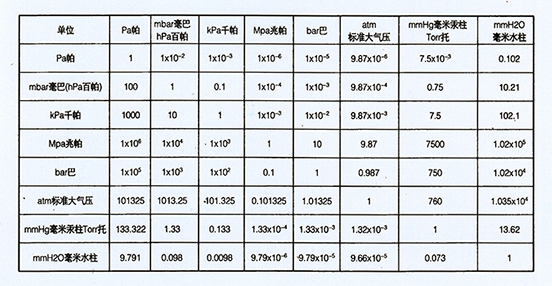

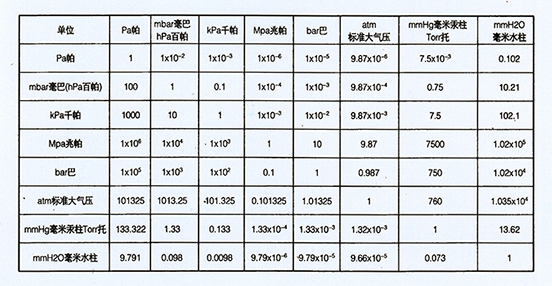

Common Pressure

Unit Conversion Table

|