|

Product Overview

The KDW series multi - stage pumps

are the latest generation of multi -

stage pump products newly developed

and designed by Jiangsu Kaifeng Pump

& Valve Co., Ltd. Their excellent

hydraulic performance and structural

features ensure that users can

effectively reduce the operating

costs of the pumps in various

application scenarios.

Technical Parameters

Pump Port Diameter:

Suction 40 - 250mm, Discharge 25 -

200mm

Flow Rate: Up to

500m³/h maximum

Liquid Temperature:

Maximum ≤80 ℃

Head: Up to 360m

maximum

Direction of Rotation:

When viewed from the motor side, the

impeller rotates clockwise

Shell Pressure: Up to

4.0MPa maximum

Product Standard: Q/FP

2104 Centrifugal Pumps for General

Purposes

(Shell Pressure - Bearing Capacity =

Inlet Pressure + Shut - off Head)

Shaft Seal Type: Packing

Seal or Mechanical Seal

Application Fields

The KDW series multi - stage

centrifugal pumps are mainly used

for pumping clean water and liquids

containing trace impurities with

physical and chemical properties

similar to water. They can be widely

applied in the following fields:

paper mills, waterworks or water

supply companies, liquid booster

devices, circulation and cooling

systems, fire protection,

refineries, water conservancy

irrigation, high - pressure water

stations, etc.

Product

Features

This type of pump is a multi - stage

centrifugal pump with segmented,

horizontal, and closed impellers,

including 10 size specifications.

Each specification has 2 to a

maximum of 10 impeller stages, and

it adopts a unique axial force

balancing mechanism: a combination

of balancing holes (double - seal

rings), labyrinth - type throttling

sleeves, and pressure - relief

pipes. The residual axial force is

borne by a set of angular contact

ball bearings.

Each type of pump can be equipped

with impellers of different

diameters, meeting users' diverse

performance requirements and

reducing power loss.

For pumps with specifications KDW25

- KDW80, the pump feet on the

suction section side are located on

the first - stage intermediate

section, and the suction port

direction can be adjusted

appropriately to adapt to different

installation conditions.

The drive end is located on the

suction section side of the pump.

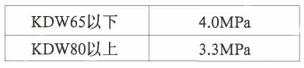

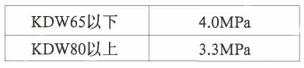

Shell pressure -

bearing capacity:

The Relationship Between Pump

Dimension Specifications and

Pressure Bearing Capacity of Casing

Components

Nozzle

Position:

When viewed from the motor end, the

pump's suction port faces

horizontally to the right, and the

discharge port faces vertically

upward. For pumps in the KDW25 -

KDW80 specifications, the suction

port direction can be adjusted to

the left according to the user's

pipeline layout. When the number of

stages is three or more, the suction

port can also be positioned

vertically upward (please specify

these requirements when placing your

order).

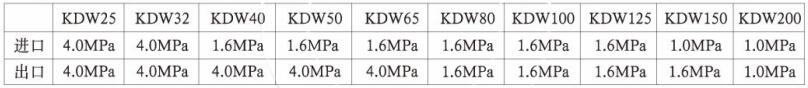

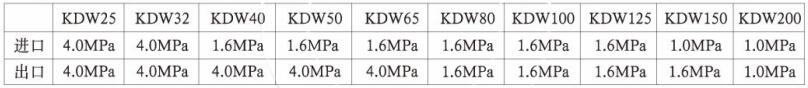

Flanges:

The inlet and outlet flanges comply

with the standard: GB/T 17241.6 -

1998 neq ISO 7005.2:1988. The

applicable nominal pressure ratings

for the flanges are as follows:

Note:

The inlet flange is of a larger

diameter, while the outlet flange is

of a smaller diameter. For the same

nominal diameter, the flange

dimensions for a nominal pressure of

4.0MPa are also applicable to those

for nominal pressures of 1.0MPa,

1.6MPa, and 2.5MPa.

Bearings:

The standard configuration is NSK -

brand bearings. The suction end

adopts cylindrical roller bearings,

and the discharge end uses angular

contact ball bearings. The bearings

are filled with No. 3 complex

lithium - based grease before

leaving the factory.

Shaft Seals:

According to the usage requirements,

the shaft seal can be either a

packing seal or a mechanical seal.

The mechanical seal is the standard

configuration. The installation

dimensions of this series of

mechanical seals comply with the

DIN24960 standard, and the CRANE2100

- type mechanical seal is selected.

Sealing Rings:

All the sealing rings are made of

fluoro - rubber (FPM).

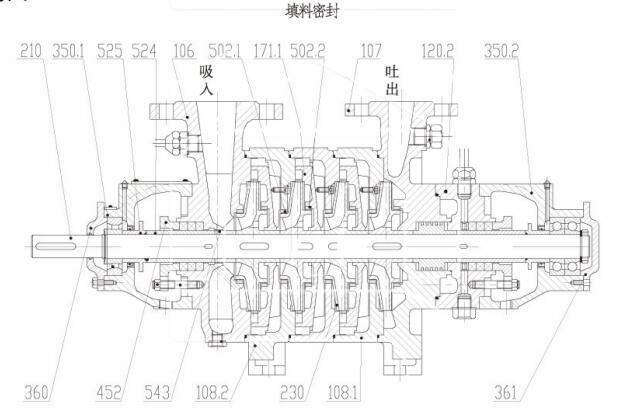

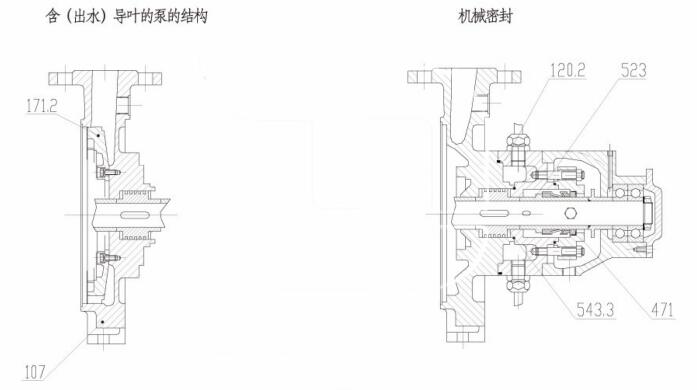

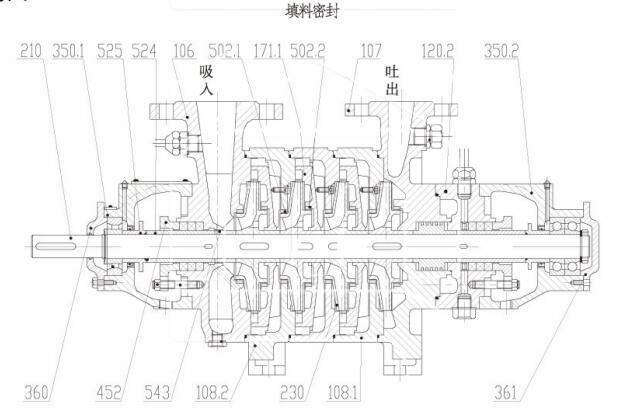

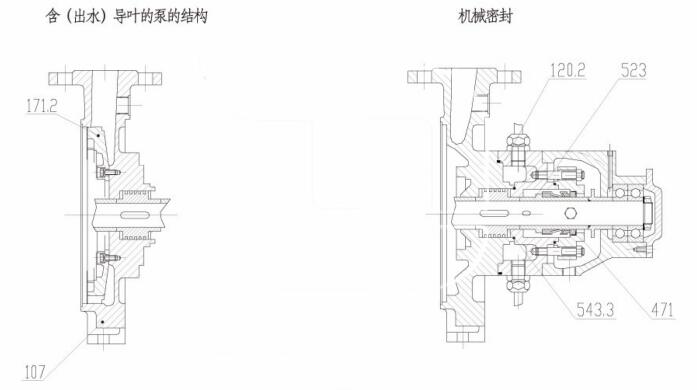

Schematic Diagram of the Pump:

|

106-Suction

Section |

107-Discharge

Section |

108.1-Intermediate

Section |

108.2-Intermediate

Section |

|

120.1-Additional

Section |

120.2-Additional

Section |

171.1-Radial

Guide Vane |

171.2-Radial

Guide Vane |

|

210-Shaft |

230-叶轮Impeller |

350.1-Bearing

Housing |

350.2-Bearing

Housing |

|

360-Bearing

Cover |

361-Bearing

End Cap |

452-Packing

Gland |

457-Packing

Spacer Ring |

|

471-Mechanical

Seal Gland |

502.1-Sealing

Ring |

502.2-Sealing

Ring |

523-Mechanical

Seal Sleeve |

|

524-Packing

Sleeve |

525-Spacer

Sleeve |

543.1-Spacer |

543.3-Spacer |

|