|

Overview

The IHF series fluoroplastic pumps

independently developed by our

company are single-stage,

single-suction cantilever

centrifugal pumps. Their marking and

rated performance comply with the JB/T8688-1998

standard. The product features

reasonable design, compact

structure, reliable performance,

stable operation, long service life,

and convenient operation and

maintenance.

The wetted components of IHF

fluoroplastic pumps are made of

high-strength materials such as F46,

reinforced polypropylene, or

ultra-high molecular weight

polyvinyl chloride (UHMWPE).

According to the usage

characteristics of centrifugal

pumps, the wetted components, pump

casing, impeller, etc., adopt a

steel-lined plastic process to

eliminate the defect of insufficient

strength in all-plastic casings. It

can replace 316L stainless steel,

Monel alloy, Hastelloy, high-alloy

stainless steel, and ultra-low

carbon stainless steel in strong

acid media below 100°C, and is

widely used in industries such as

petrochemical, chemical, metallurgy,

pesticides, papermaking,

environmental protection,

electroplating, paint, and power.

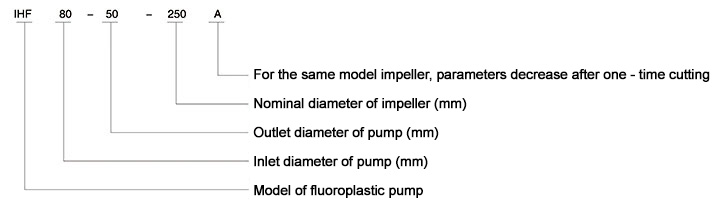

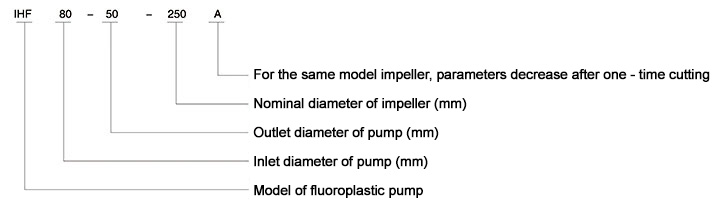

Model

Description

Application Scope

Chlor-Alkali Industry:

Caustic soda solution,

electrolyte, brine for

ion-exchange membrane caustic

soda production, chlorine water,

sodium hypochlorite,

hydrochloric acid, sulfuric

acid.

Nonferrous

Metal Smelting:

Transportation of various acid

solutions, electrolytes, sewage,

and other media in

hydrometallurgical processes.

Iron and Steel

Industry:

Electroplating, pickling, etc.

Acid Production

Industry:

Hydrochloric acid, nitric acid,

sulfuric acid, phosphoric acid,

acetic acid, etc.

Paper Industry:

Chemical reagents, bleaching

solutions, sewage, etc.

Fermentation

Industry:

Intermediates, lactic acid,

citric acid, food additive NaCV

(sodium chloride?), beer,

various fermentation slurries,

etc.

Environmental

Protection:

Various chemical reagents,

acid-base-containing wastewater,

etc.

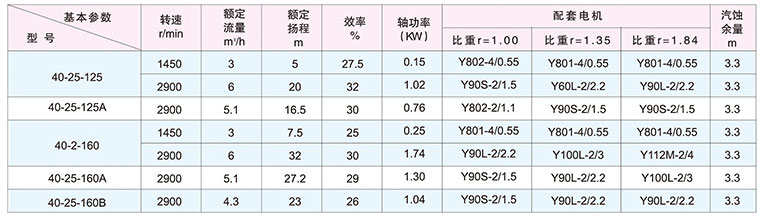

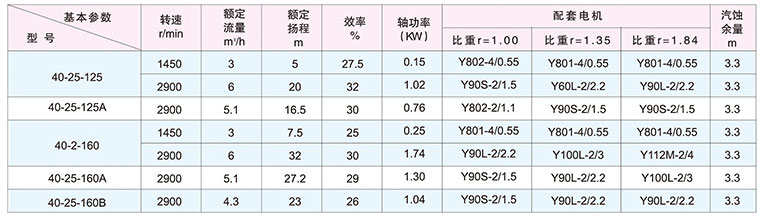

Performance Parameters

|