|

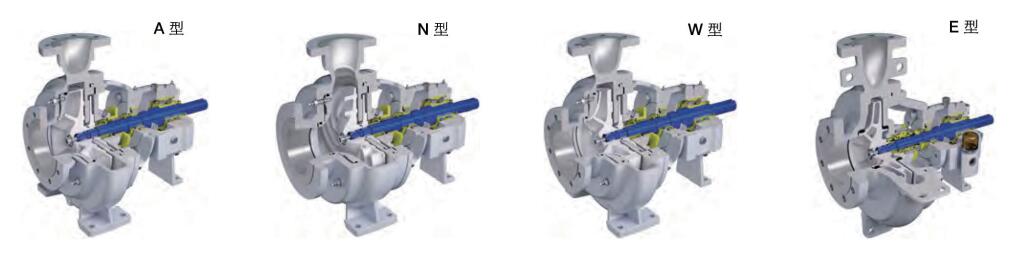

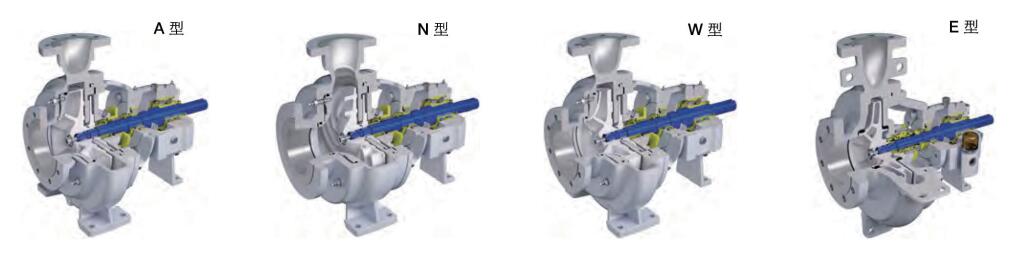

End - suction single - stage

centrifugal pumps include types A,

N, W and E. Their design complies

with international standards ISO5199

and ISO2058. Through long - term

research and development, they have

surpassed industry market standards

and ensured excellent performance

and reliability.

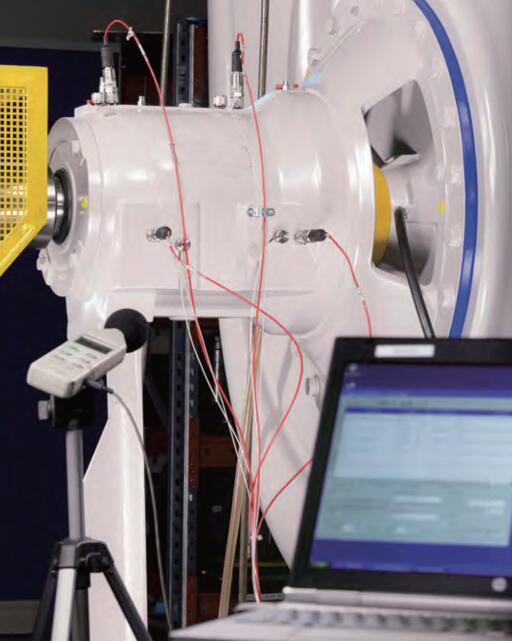

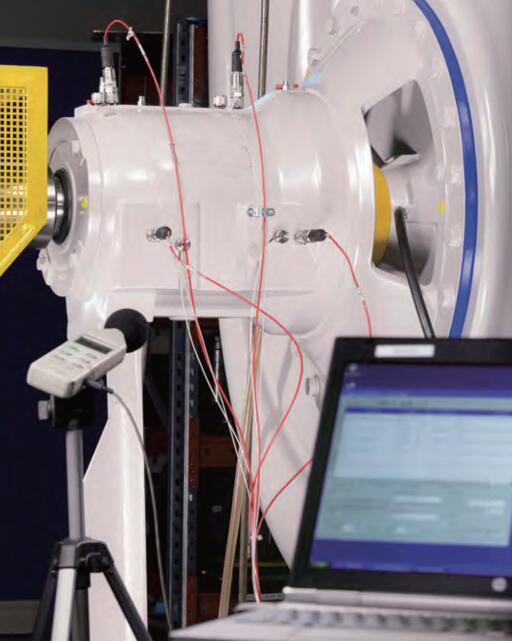

Hydraulic Design Simulation &

Comprehensive Testing Laboratory

Through innovative methodologies, we

have significantly enhanced the

performance and reliability of our

pump products. At Jiangsu Kaifeng,

technological innovation, research,

and development are our top

priorities. Using our proprietary

simulation tools, we can rapidly

analyze various hydraulic designs

and simulate real-world operating

conditions in our comprehensive

large-scale laboratory to test all

pump operation states.

Hydraulic Range Meets Most Operating

Conditions

The design of end - suction single -

stage centrifugal pumps can meet the

application requirements of most

hydraulic coverage, enabling ideal

pumping of various challenging

fluids.

- Petroleum and Natural Gas

- Vertical Processing Industry

- Power Industry

- Pulp and Paper

- General Industry

- Chemical Process

- Water and Sewage

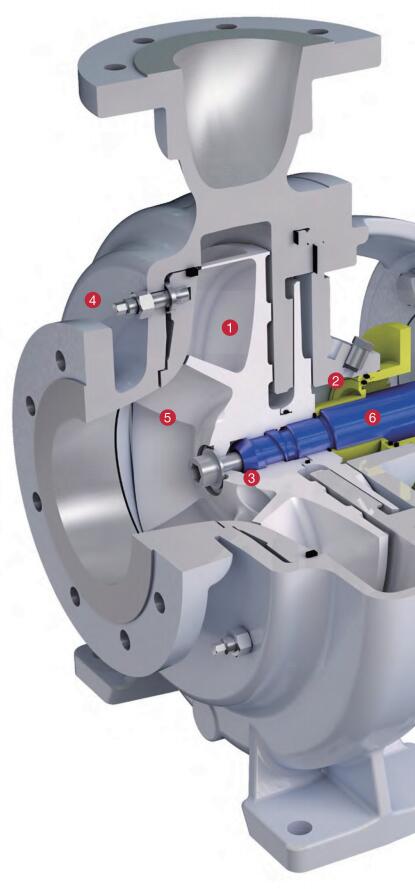

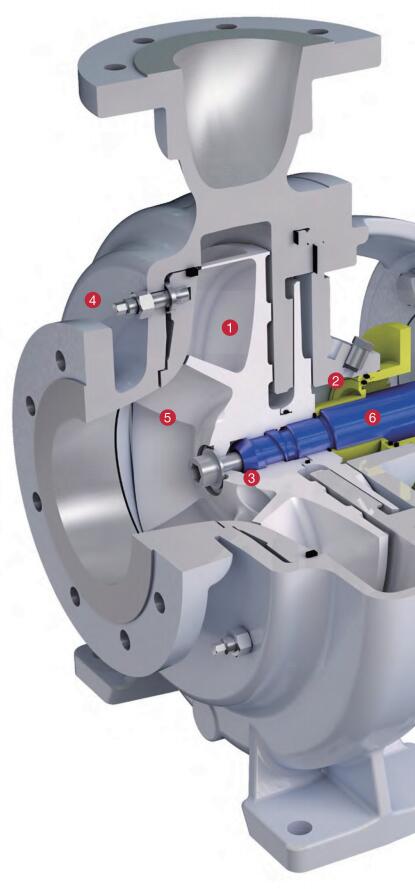

Features

and Advantages Features

and Advantages

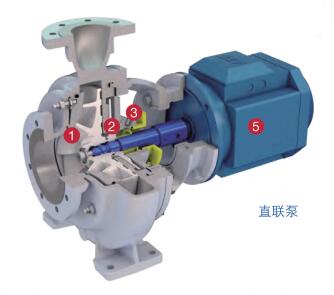

1、Reliable

and Efficient Universal EnerSave™

Impeller

•

Reduces lifecycle costs, energy

consumption, operation, and downtime

costs.

2、Innovative

and Reliable Integrated Degassing

and Self-Priming Unit

•

Designed for challenging liquid

applications under various operating

conditions.

•

Built-in vacuum pump helps the

centrifugal pump start when the

liquid level is below the pump in

some self-priming scenarios.

3、Patented

Rotokey Impeller Mounting for High

Strength and Reliability

•

Enables simple and quick disassembly

and reassembly.

•

Minimizes maintenance costs.

4、Externally

Adjustable Patented Wear Plate

Design

•

Allows easy and fast adjustment of

impeller clearance to maintain

continuous high efficiency and

minimize pump lifecycle costs.

5、专利设计的平衡孔Patented

Balanced Hole Design

•

Ensures efficient liquid circulation

on the back of the impeller and in

the seal chamber.

•

Maximizes reduction of operation and

maintenance costs by minimizing

unexpected downtime, while ensuring

optimal shaft seal performance.

6、Reliable

WaterLess™ Shaft Seal

•

Offers efficient dynamic seals,

single mechanical seals, double

mechanical seals, and packing seals.

•

Easy and quick to install.

•

No measurement required.

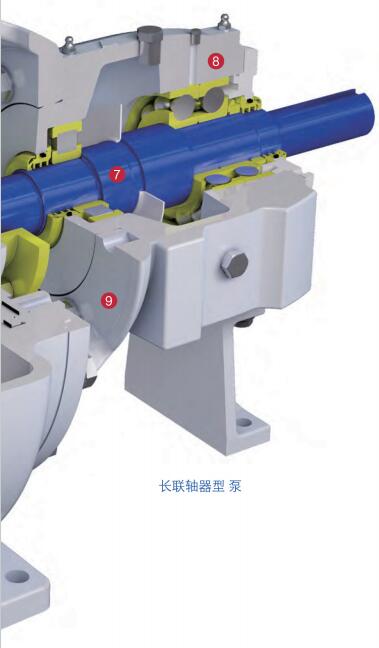

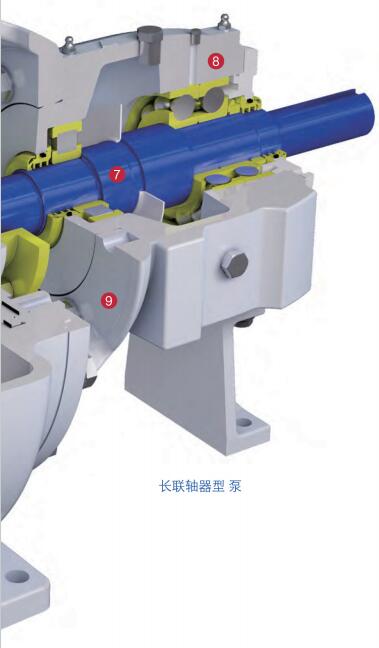

7、High-Strength

Shaft 7、High-Strength

Shaft

•

Reduces shaft deflection at the

stuffing box to <0.05 mm / 0.002 in.

•

Helps prolong shaft seal service

life, reduce unexpected downtime,

and lower maintenance costs.

8、Reliable

Bearing Unit

•

A reliable, simplified heavy-duty

bearing unit minimizes unexpected

downtime, thereby reducing shutdown

and maintenance costs.

•

Bearing units include oil and grease

lubrication to fully meet various

requirements:

Grease lubrication for applications

up to 120°C/250°F.

Oil lubrication for applications up

to 180°C/355°F.

9、Set

Screws

•

Ensure simple and quick disassembly

to reduce maintenance costs.

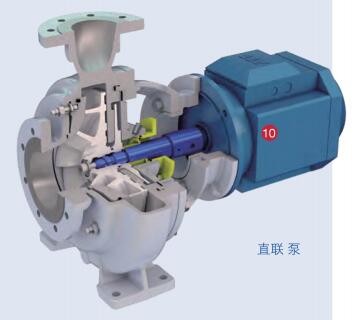

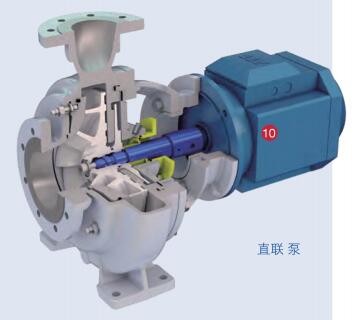

10、Standard

IEC Flange or Flange/Foot-Mounted

Motors with Heavy-Duty Bearing Units

•

Heat-fitted solid shaft connections

with the same shaft dimensions as

long-coupling-type pumps.

•

Flow-through components and seal

units have identical

interchangeability.

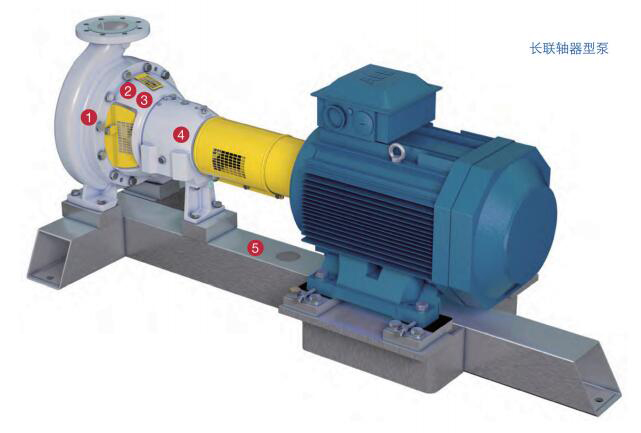

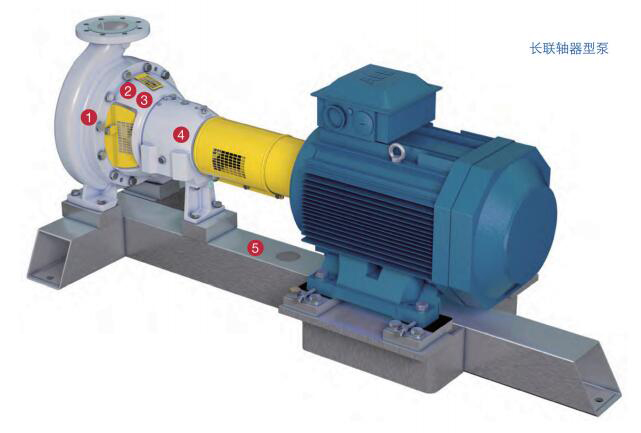

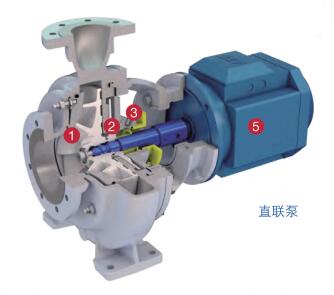

High-End Design Minimizes Lifecycle

Costs

① Jiangsu Kaifeng EnerSave™ Impeller

② Jiangsu Kaifeng Waterless Shaft

Seal Unit

③ Innovatively Designed Degassing

and Self-Priming Unit

④ Reliable Bearing Unit

⑤ Simple and Quick Installation

|

Features

and Advantages

Features

and Advantages 7、High-Strength

Shaft

7、High-Strength

Shaft