|

Overview

The KSJ - type pulp pump is a new -

type pulp pump designed by absorbing

advanced foreign technologies based

on the characteristics of three -

phase (solid, liquid, gas)

transportation of pulp. It not only

has a wide performance range and

small parameter intervals, but also

adopts a unique design concept, thus

saving energy, increasing the

bearing capacity of the pump, and

prolonging its service life.

Performance Range of KSJ Series

(Calculated at Design Point)

● Rotational speed: 1450r/min

and 980r/min

● Flow rate: 20 - 1600m³/h

● Head: 8 - 50m

● Pulp consistency: ≤6%

● Operating temperature: ≤100℃

Structural Features

Impeller: Adopts

a fully - open large - flow -

channel precision casting with 3 - 6

blades. This structure can greatly

reduce the axial force, and it is

not easy to accumulate bubbles and

block the flow channel during the

transportation process, improving

the pulp transportation consistency.

Volute: Adopts a

single - stage volute casing. Large

- size casings are designed as

double - volute structures to reduce

radial force and shaft deflection.

Material: Commonly -

used materials for wetted components

include QT600 - 3, ZG45, ICr18Ni9Ti,

wear - resistant alloy, CD4MCU.

Shaft Seal: Mechanical

seal and packing seal are available,

and users can choose as needed.

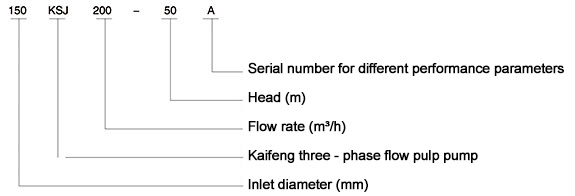

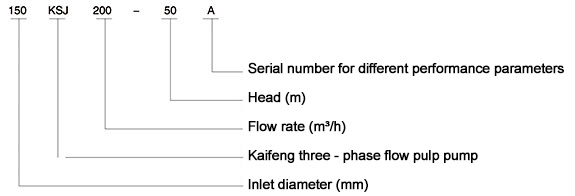

Model

Explanation

|