|

――Low Consumption High

Efficiency

Suitable for all kinds of stock in

thechests or towers for

consistencies below 6.5%.

|

|

|

|

|

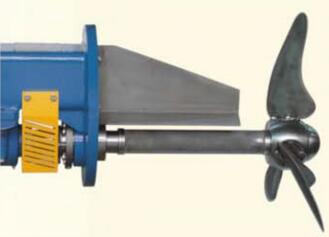

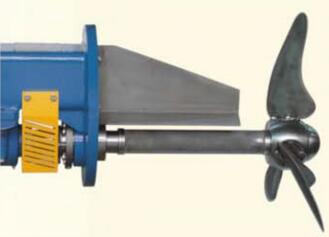

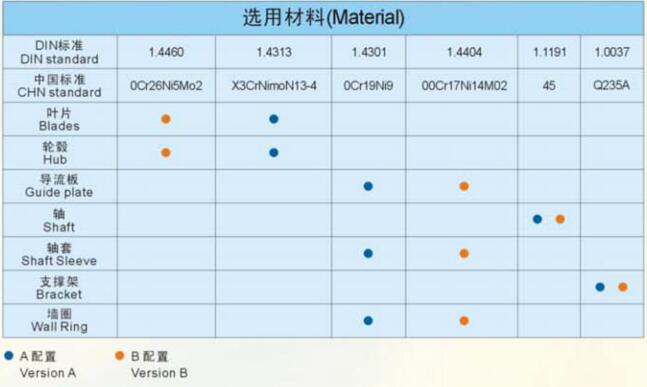

• All parts in contact

with the medium aremade of

stainless steel.

• The agitator blades

can be easily adjusted to

fulfill

differentrequirements. |

• A strong guide plate

protects the shaft and

improvesmixing efficiency.

• A wear sleeve

prevents shaft wearing. |

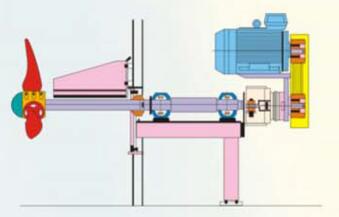

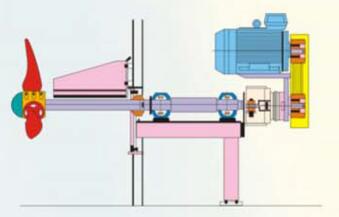

• With propeller

diameter exceeding 1300mm, a

gearbox and belt pulley is

used to reducethe speed.

|

|

|

|

|

|

• Lock washer prevent the

blades from loosening.

|

• Taper locks are used

for a simple assembly

andadjustment of the belt

pulleys . |

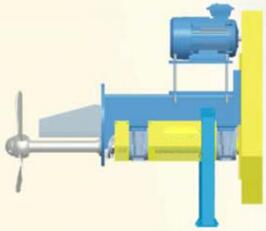

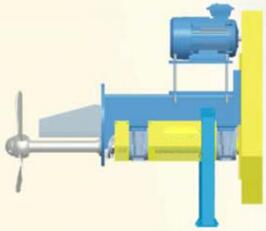

• Optional legs for

MzJ1000/MzJ1300 to give

additional support to the

agitator when mounted on a

weak chest. |

|

|

• Agitators up to

1300mm diameter are directly

fixed to the chest and do

not need an extra

foundation.

• Correctly

dimensioned shafts and

bearings ensure the

agitators operate very

smoothlyand in a stable

manner.

• The bearings are

placed on the outside of the

chest and can be easily

replacedwithout emptying. |

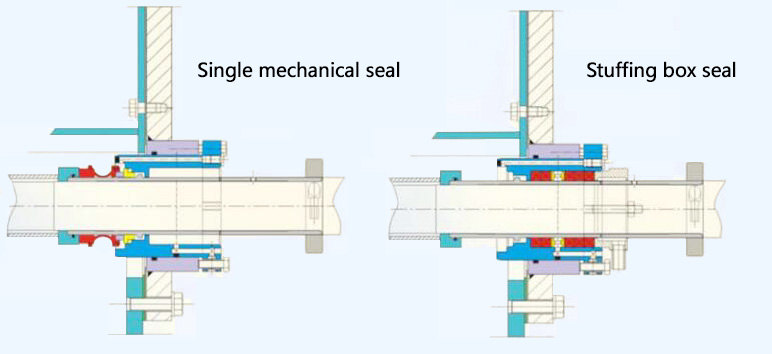

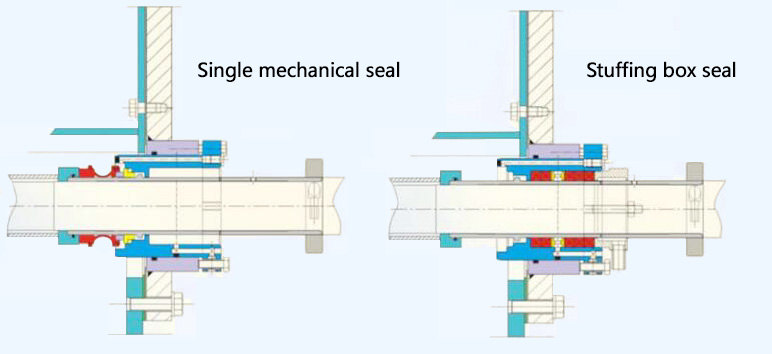

Available seals

• Gland packing and

mechanical seal are

available.

• Packing can be

replaced from the outside

without emptying the chest.

• ptional ceramic

coating for the stuffing box

sleeve enhances wear life.

Selection

of agitators Selection

of agitators

Careful selection of our agitators

to suit your requirements ensures

operation with the lowest possible

power consumption.

Factors affecting selection of

agitators include:

• Size and shape of chest or tower

• Object of agitation (storage or

mixing)

• Residence time

• Temperature of medium

• Consistency of medium

• Type of pulp / stock

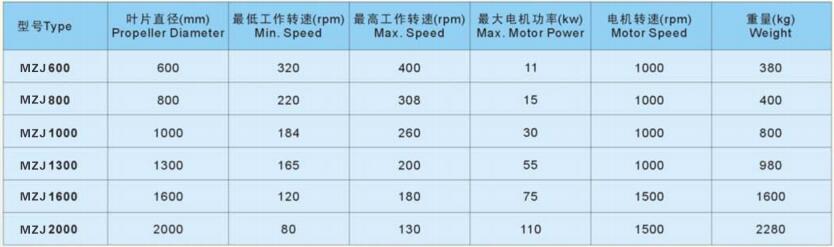

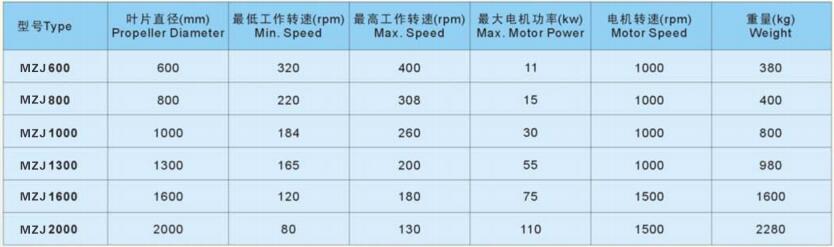

Technical data

|

Selection

of agitators

Selection

of agitators