|

Summary

In the media being pumped, gases or

air often inevitably exist, which

can lead to instability during the

pumping process. To achieve stable

pumping of media containing a high

amount of air, remove the gases

within the media during pumping, and

address scenarios where the pump's

inlet pipe often lacks liquid and

requires self-priming functionality,

Jiangsu Kaifeng has successfully

developed the AD pump. This pump

features a built-in water ring

vacuum pump behind the main pump

impeller, combining self-priming and

degassing capabilities.

The AD pump has two functions:

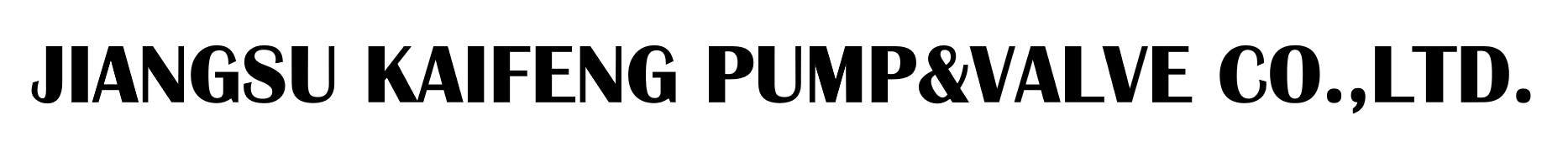

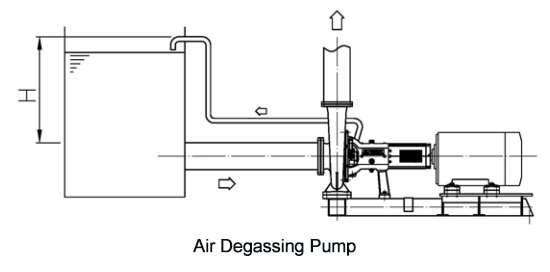

1��Air Degassing Pump

When used as a degassing pump, it

can stably pump media with an air

content of <8% (concentration 0�C6%)

through degassing. The return height

H of the degassing pipe can reach 6

meters, and the pulp-gas mixture can

be directly returned to the pulp

pool to avoid pulp loss.

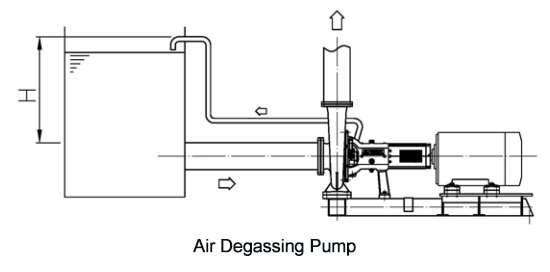

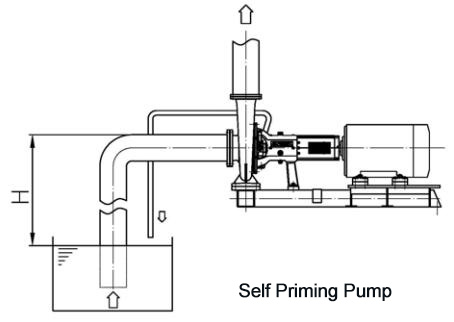

2��Self Priming Pump

When used as a self-priming pump, it

has a strong self-priming capacity,

with a self-priming height H of up

to 6 meters.

Note: The

interface configurations of the

degassing pipes differ between

self-priming pumps and degassing

pumps. Please specify the required

application mode in the order.

Structure

Single-stage, single-flow,

volute-type vortex pump. Based on

its process design, the impeller,

built-in vacuum pump, shaft seal,

and bearing housing can be

disassembled and/or installed as a

"cartridge unit" without

disconnecting the suction and

discharge pipes.

Impeller

A specially designed semi-open

impeller with three main vanes and

multiple back vanes, featuring high

efficiency, abrasion resistance, and

non-clogging capabilities.

Built-in Vacuum Pump

The built-in water ring vacuum pump

is located behind the main pump

impeller, sharing the same shaft for

compact structure, strong degassing

capacity, and low power consumption.

Bearings

The pump shaft is supported by

imported SKF bearings lubricated

with oil or grease. Cylindrical

roller bearings are installed on the

pump end, while two angular contact

ball bearings are mounted

back-to-back on the drive end. The

oversized shaft ensures

vibration-free operation.

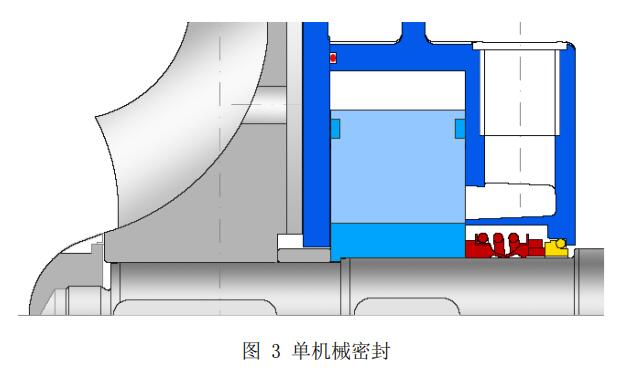

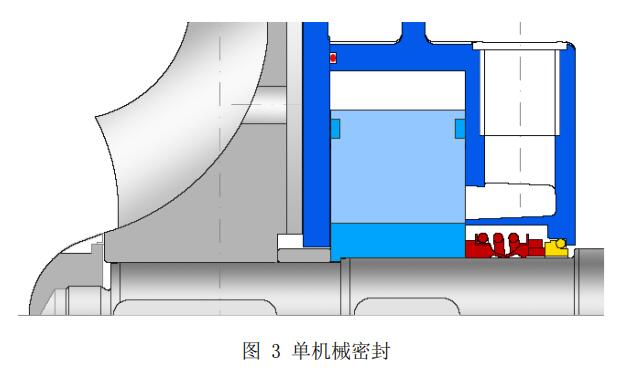

Shaft Seal

Single mechanical seal.

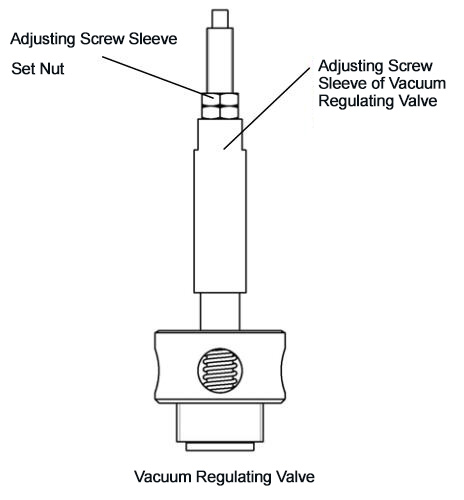

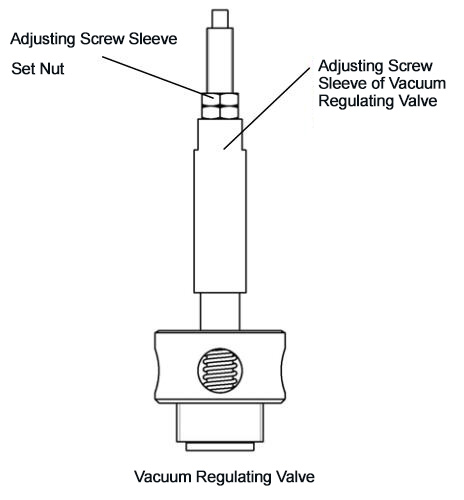

Vacuum Regulating Valve V-1

Vacuum Regulating Valve V-1 is

roughly adjusted at the factory. Its

function is to enable the vacuum

pump to obtain the required stable

vacuum degree (e.g., -0.5 to -0.6

bar) by adjusting the adjusting

screw sleeve of the vacuum valve.

This eliminates the screaming noise

generated in the pump due to high

vacuum and ensures that the vacuum

pump operates in a low-power

consumption and stable state.

Vacuum Gauge W-1

The Vacuum Gauge W-1 displays the

vacuum degree of the built-in vacuum

pump, with a measurement range of 0

~ -1 bar (0 ~ -0.1 MPa).

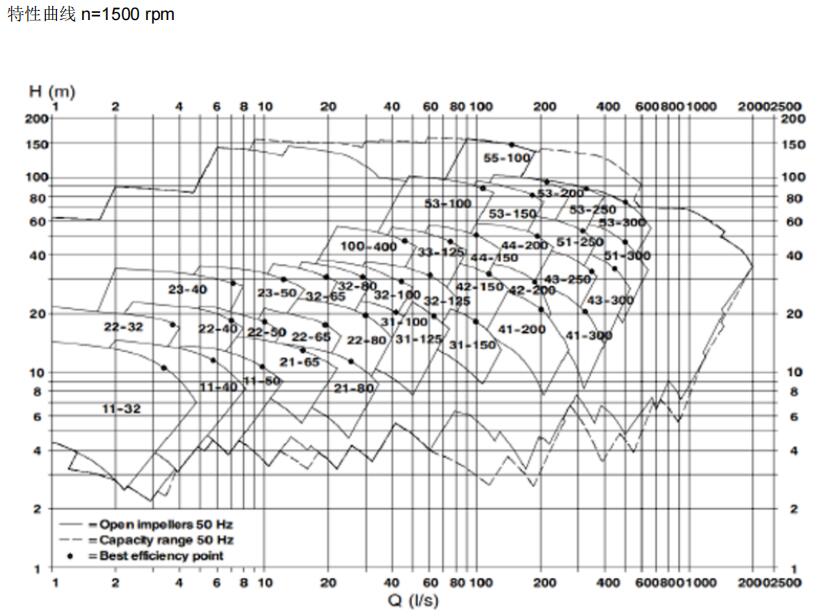

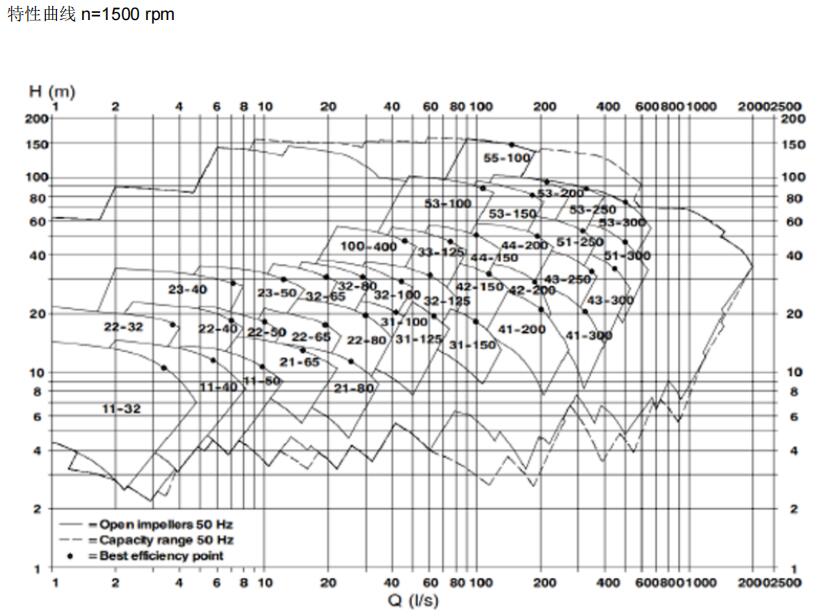

Technical Data

The AD-type pump is available in

multiple specifications. For

detailed data of the pump you

purchased, please refer to the data

sheets, characteristic curves,

dimension drawings, and sectional

diagrams in the appendix.

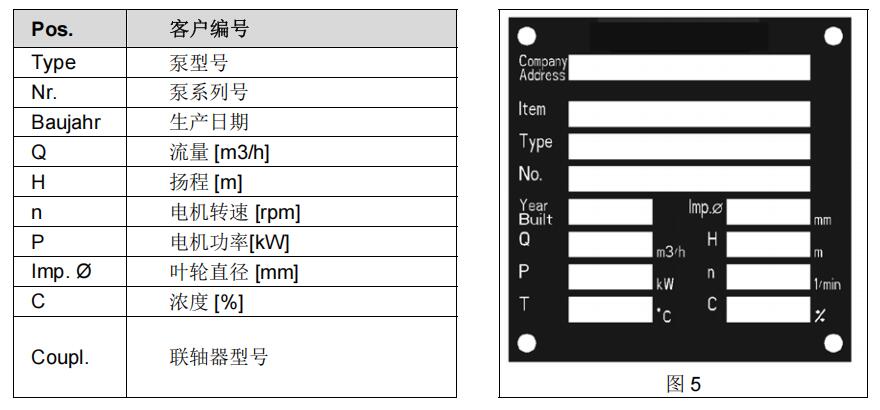

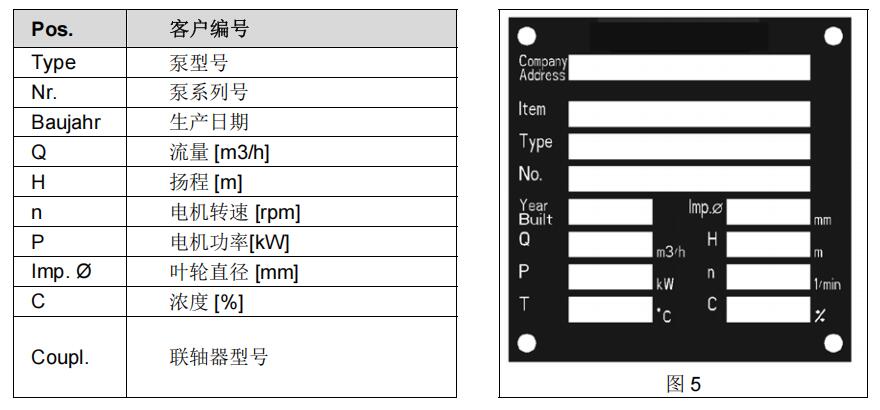

Nameplate

Each pump is equipped with a

nameplate fixed on the pump body,

providing important information

related to the pump.

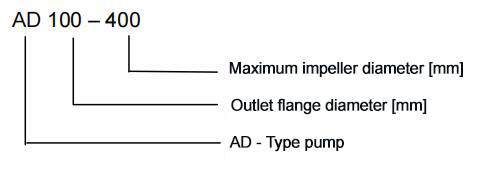

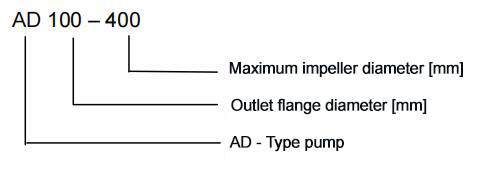

����Pump

Design

Characteristic Curves

We can provide various models of AD

pumps.

Note:

The above are standard models for

degassing conditions. For self -

priming conditions, add "S" after

the model number, e.g., AD100 -

400S.

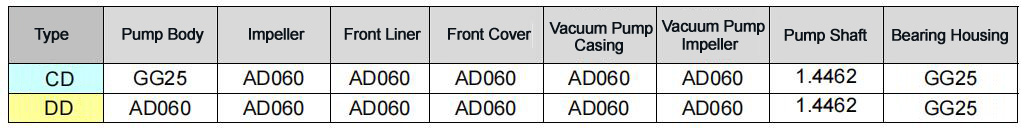

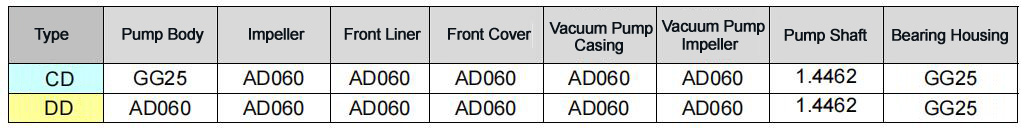

Selection of Component Materials

To suit different operating

conditions, we offer two material

configurations for your choice:

|