|

Overview

This screw pump can be used to

transport neutral or corrosive

liquids, clean or abrasive liquids,

liquids containing gas or prone to

foaming, and high or low viscosity

liquids, including those with fibers

and solids. It is mainly applied in

industries such as food, textiles,

paper-making, petroleum, chemicals,

alkali and salt production,

shipbuilding, construction, nuclear

industry, metallurgy, and mining.

Working Principle

The single-screw pump is an

internally meshing closed-type screw

pump belonging to the positive

displacement rotor pump category.

Its main working components consist

of a stator with a double-helical

cavity and a single-helical screw

rotor that meshes within the stator

bore. When the input shaft drives

the rotor via a universal joint to

perform planetary rotation around

the stator, the stator-rotor pair

continuously forms closed cavities.

These cavities move axially at a

constant speed with unchanged

volume, conveying the medium from

the suction end through the

stator-rotor pair to the discharge

end. The medium sucked into the

closed cavity flows through the

stator without being agitated or

damaged. Therefore, it can transport

media containing hard abrasive

impurities or solid particles, as

well as viscous liquids.

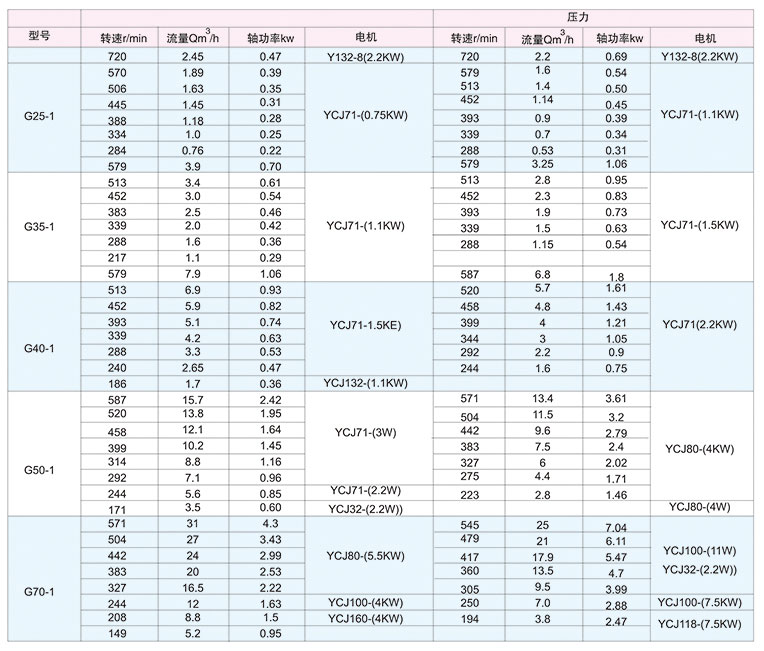

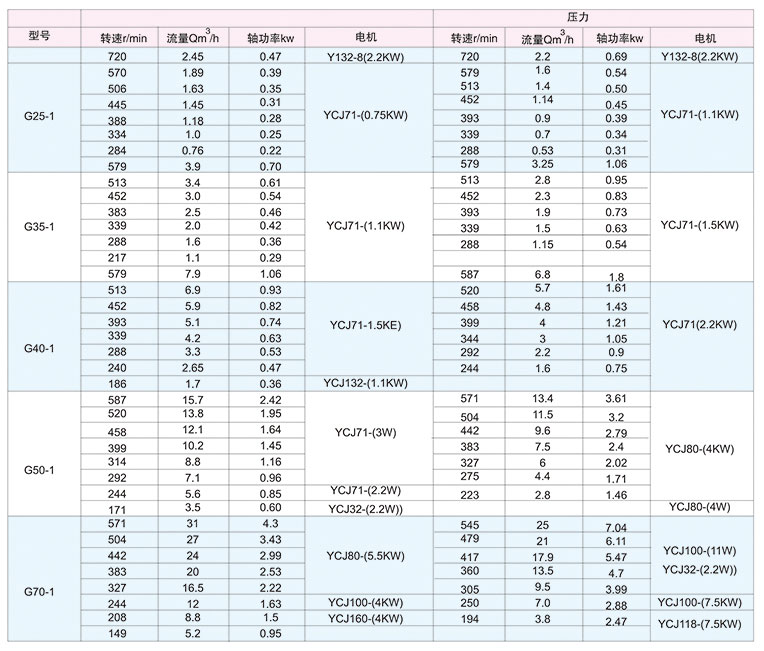

Technical Parameters

|