|

Expertise, Reliability & Research

Jiangsu kaifeng has rich experience

in providing inno-vativepumping

solutions to business partners in

the following industries:

|

Metal & Mining |

Pulp and Paper |

Power |

Oil & Gas |

Chemica |

Food |

Municiple |

General Instria |

Expertise

Jiangsu kaifeng'success is founded

on expertise.Our know how and

competitiveness is based on close

cooperation with the world's leading

pulp and paper producers, and

engineering companies. These same

principals have also led to success

in the food.metals and fertilizer

markets as well as other related

industries. Jiangsu kaifeng is your

safest choice for every pumping

application in your mill or factory.

Reliabililty

The reliability of your pumping

system depends on the product

design,the manu-facturing and

delivery process,the right hydraulic

selection , aftermarket service and

support. Just ringt, our success

bassed on these points.

Research

Research and development have always

received top prior-ity at Jiangsu

kaifeng. Jiangsu kaifeng focuses on

customer demand,we select the best

matched with diffierent applications

for Pulp &paper,Metal,Mining,Food.

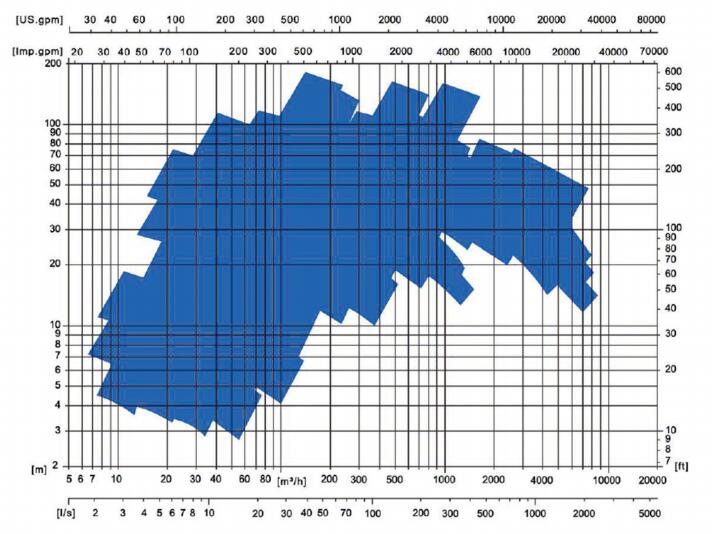

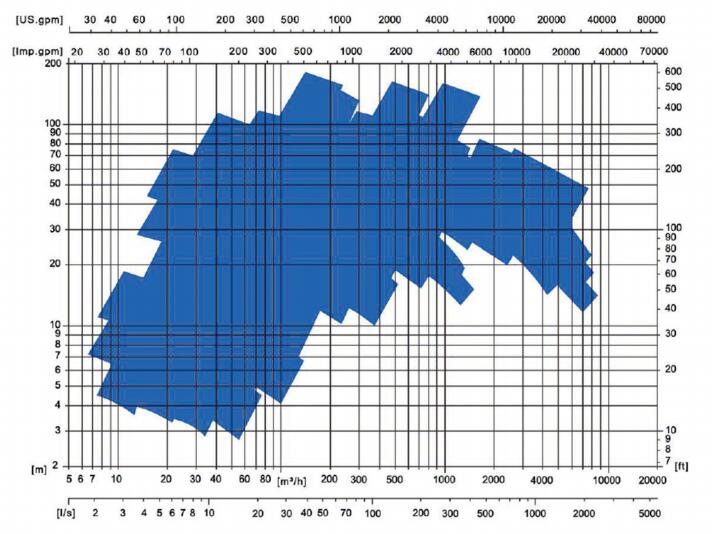

Wide

Hydraulic Coverage

ACP Performance

Head up to 160 m.

Temperature max.200°c

Capacity up to 2100 l/s

Operating frequencies 50 Hz

Pressure up to 2.5 MPa,

(depending on material and size)

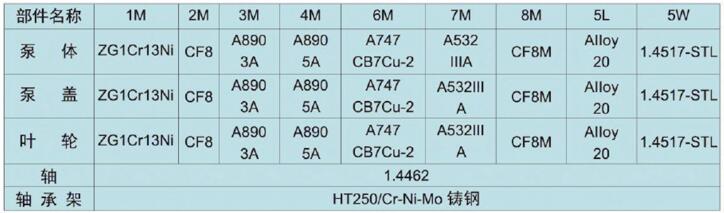

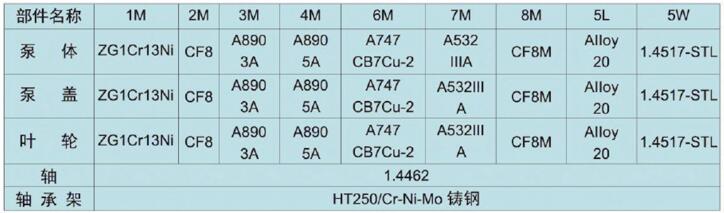

Other corrosion resistant cast

steels available on special request.

Other

Pumps

•

The non-clogging and the wear

resistant pumps from the ACP-P-plus

series can be used in special

applications as follows :

•

The ACP-CL series pumps with central

support mount are intended for

pumping liquids with high

temperature.

•

The ACP-W series pumps feature

specially designed wear resistant

hydraulics with materials that can

withstand the most abrasive and

erosive pumping applications.

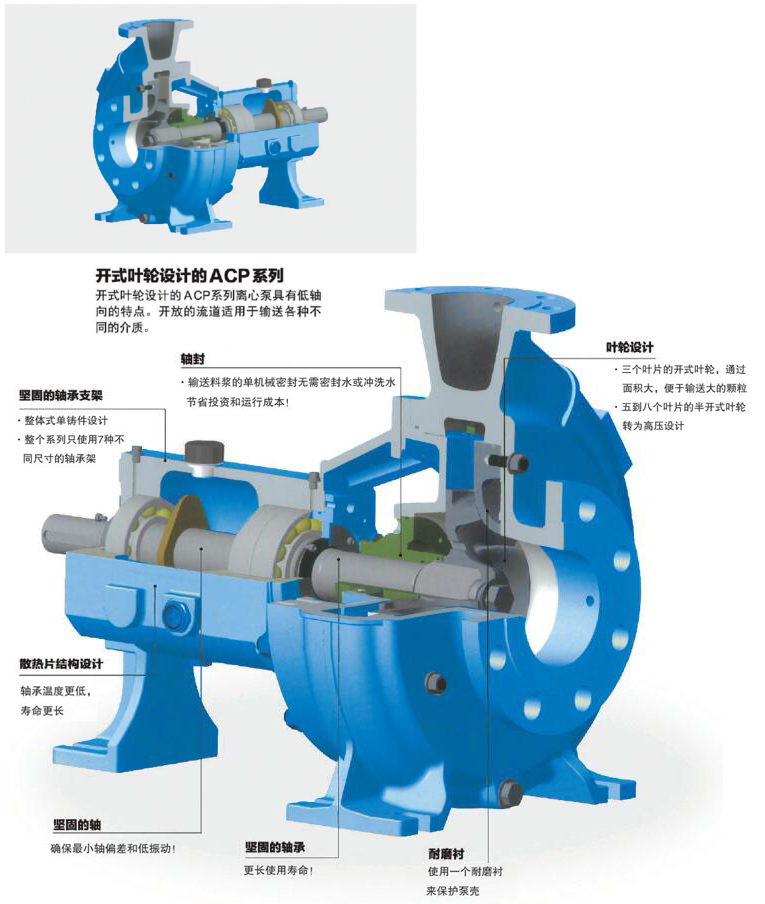

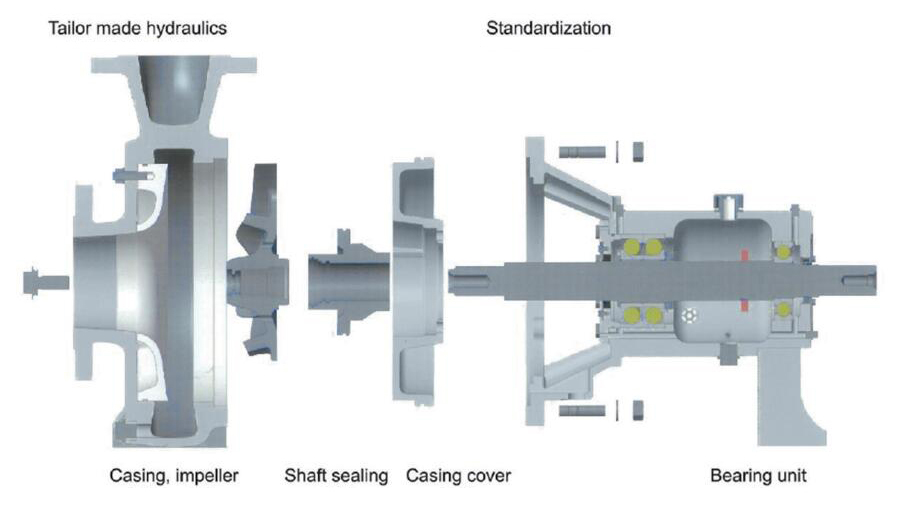

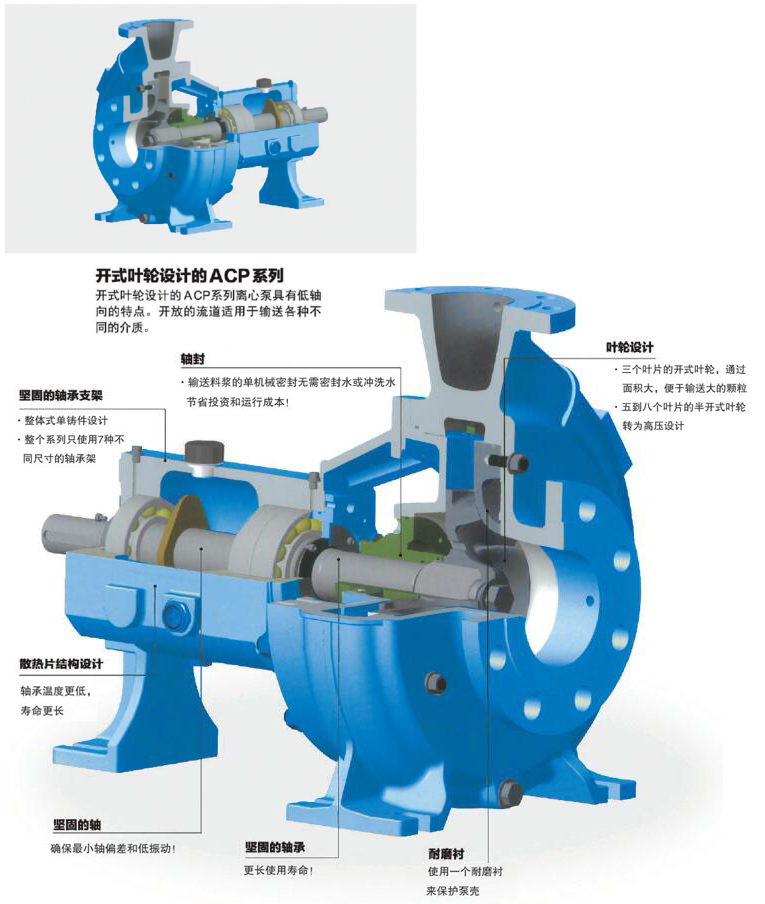

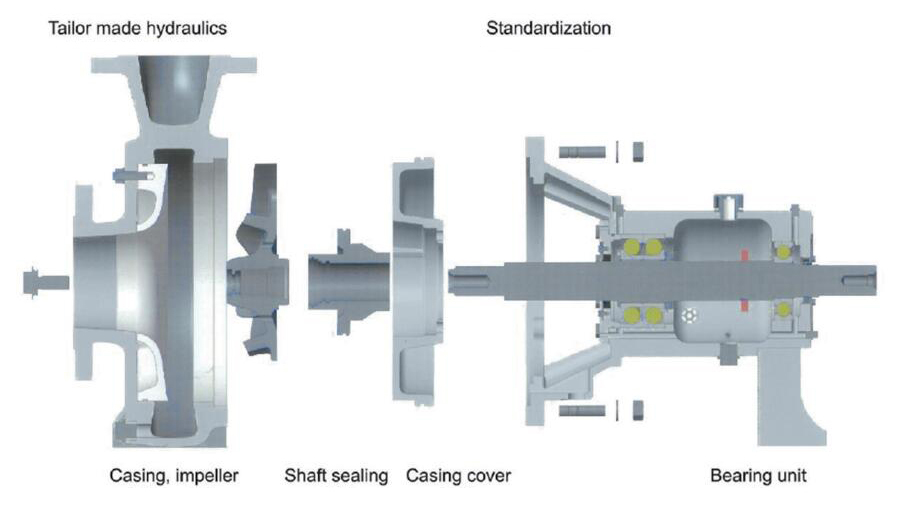

Standardization

All jiangsu kaifeng ACP pumps have

the same basic design using common

components. Only 7 bearing units

forthe whole ACP series are needed

to coverthe pumping applicationsin

most industries.The hydraulics

(casing and impeller) are tailor

made according to the pumped liquid

and pumping application. Casing

cover , sealing parts, coupling as

well as the common baseplate are

highly standardized.High modular

inter-changeability gives lower

spare inventory costs.

Hydraulic Design

•

The jiangsu kaifeng ACP product line

offers a wide range of hydraulic

sizesto guarantee minimum power

consumption.

•

Balance holes in the impeller are

used to stabilize the pressure in

the seal chamber.The balance holes

in opent impeller can be plugged to

optimize the shaft seal

environment,reduce

vibration,increase pump's life.

•

The impellers have several designs,

open, closed.sem-open type, to

satisfy pumping liquid with

solid,pulp,sludge an so on.

•

The back vanes of the impeller keep

the area between the impeller and

the casing cover clean, and reduce

axial loading on the bearings,and

increase pump's life.

lmpellers Tailored for Different

Liquids

|

|

|

|

|

Closed impeller |

Open impeller |

Special open impeller |

Open impeller |

|

is used for pumping

clean liquidsor liquids

containing some

impurities.

|

is designed for liquids

containing

solidparticles, abrasive

liquids or stock up high

consistency pulp. |

is suitable for liquids

containing bigger solid

particles and long

fibers, abrasive liquids

or paper stock up to 8%

consistency. |

is designed for liquids

containing solid

particles, abrasive

liquids or stock up high

consistency pulp. |

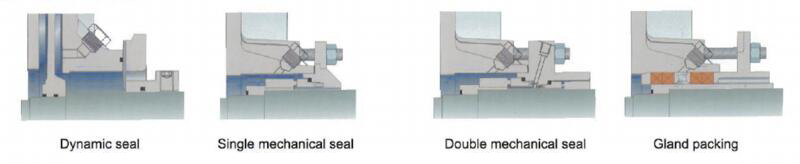

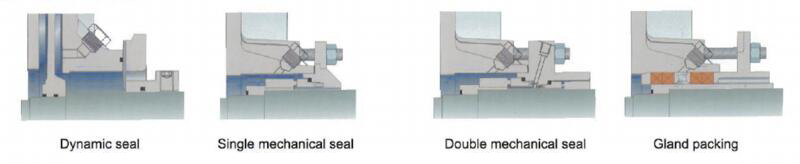

Shaft

Sealing

Dynamic seal

Dynamic Seal is specially designed

for fi brous liquids such as paper

stock and other difficult but

commonly pumped liquids. The Dynamic

Seal requires no external sealing

water. It is essentially maintenance

free and offers outstanding

reliability.

Mechanical seals

Various mechanical seal confi

gurations are available. A single

mechani-cal seal is used for many

applications with no circulation

liquid ushing with internal/external

circulation liquid or with grease is

available. For extremely demanding

liquids and application, double

mechanical seals can be selected.

Sealing liquid from an external

source is required.

Gland

packing

Gland packing with external ushing

prevents the pumped liquid

frompenetrating into the seal

housing.The pressurised ushing

liquidcauses it to ow into the

pumped liquid.Alternatively the

external ushing liquid can have a

seperate outlet connection.

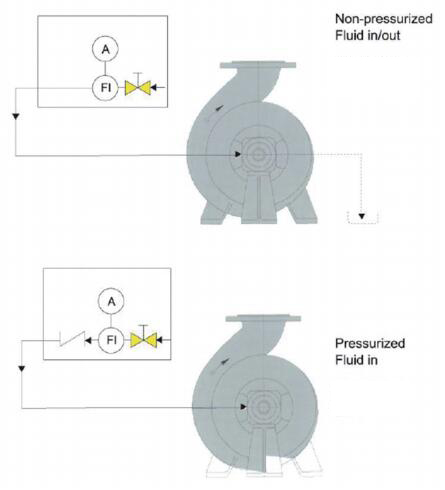

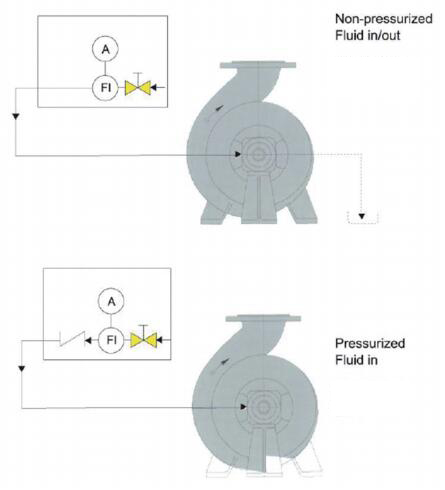

Sealing Water Equipment

The concept for sealing water

equipment meets all the requirements

demanded by the pumped liquid or the

shaft seal. All general pumping

solutions can be covered by just

four different options. Special

materials to take into account

corrosive environments ensure

reliable, operation in extreme

circumstances.

lnspection:

Laser Alignment

Pump Selection

Base-plate Design

Vane Re-design

M-seal/Flushing

Selection

Up-grade

3D Drawing |

Management:

5S

ISO |

Space:2,100m2

welding: ASME II KOC WPS/PQR

Crane: 5.0T 10T

Machining:Lathe/Drilling/Milling/Grinding

Balancing: 0.5T 2.0T

Hydraulic Pressure:2,000

PSl

ColderlHeater

Measurement Tools |

|