|

Kaifeng Pump Valve

Medium - Consistency Pump - KMC

Series

No External

Vacuum Pump Required for Maximum

Efficiency

For decades, Kaifeng Pump and Valve

has enjoyed a well - deserved

reputation for its excellence in the

design and innovation of centrifugal

pumps.

As a supplier that provides a

comprehensive product portfolio for

the pulp and paper industry, we

possess experts who are highly

proficient in the relevant process

technologies. This expertise serves

to establish a robust and enduring

foundation for our successful

advancement within the pulp and

paper industry.

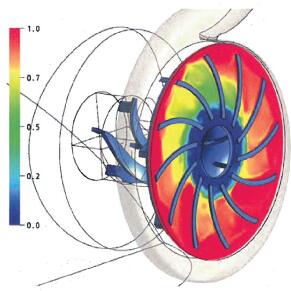

The newly - developed KMC series

medium - consistency pumps by

Kaifeng Pump and Valve have set a

new benchmark in transporting medium

- consistency pulp suspensions.

It fully meets the high-end

customers' requirements in multiple

aspects such as efficiency, service

life, ease of maintenance, economic

benefits, and reliability.

Numerous practical applications

demonstrate that the KMC series

medium-consistency pumps of Kaifeng

Pump and Valve deliver outstanding

economic benefits, achieving

one-third energy consumption savings

compared to pumps from other brands.

Application

Fields

Transportation of pulp suspensions

with absolute dry concentration up

to 16% in the pulp and paper

industry, including:

• Chemical pulp

• Mechanical pulp

• Groundwood pulp

• Wastepaper pulp

• Syrup

Design

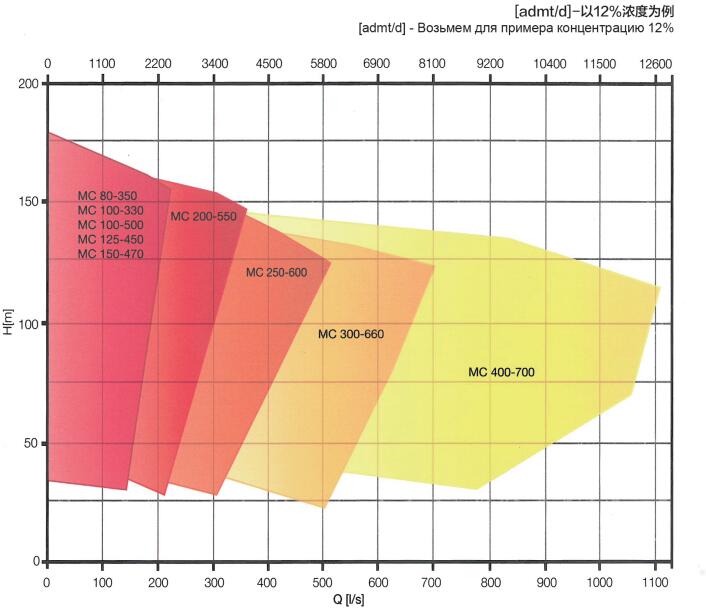

Parameters

• No built-in or external

vacuum pump required for degassing

• Maximum capacity: 1,300

air-dried metric tons per day

• Maximum head: 190 meters

• Maximum slurry temperature:

93°C (atmospheric

pressure feeding)

140°C (pressurized

feeding)

• Maximum slurry

concentration: 16%

• Maximum pressure: up to 25

kg (depending on pump size)

• Maximum efficiency: over 70%

Kaifeng Pump Valve's New

Medium-Consistency Technology

Pumping medium-consistency slurries

in the pulp and paper industry is a

complex task, and Kaifeng Pump Valve

provides a complete system designed

according to customer requirements.

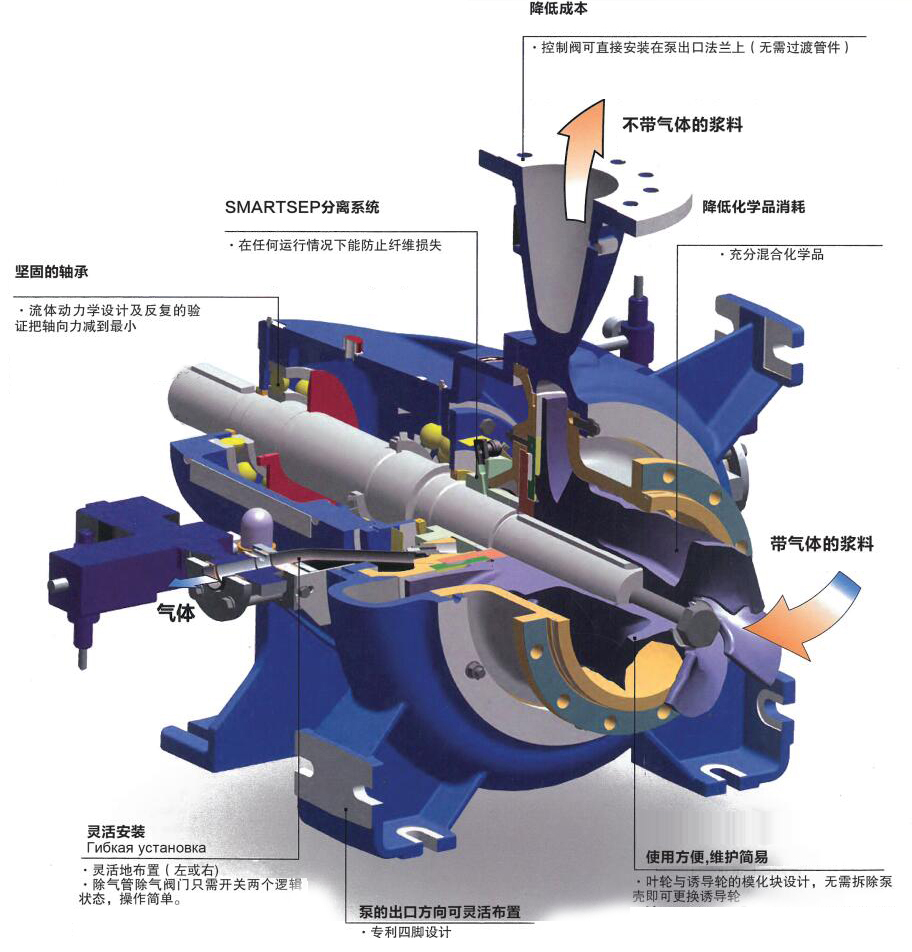

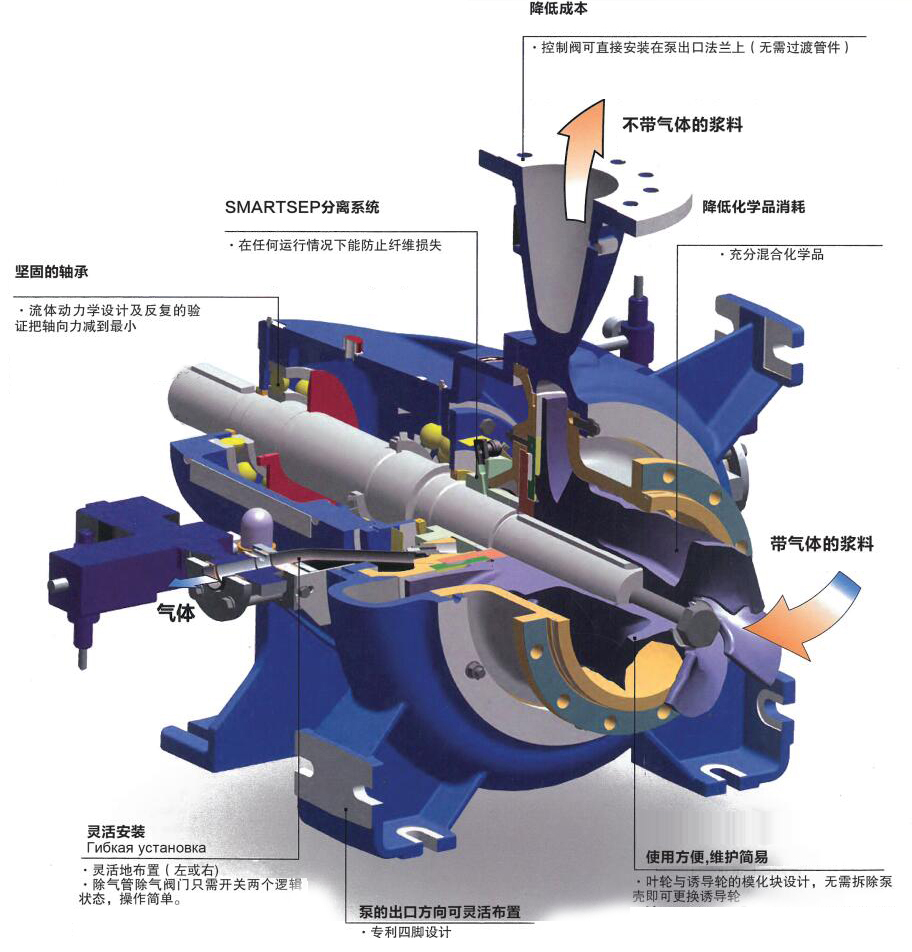

Revolutionary Design Achieves

Ultra-High Reliability

Medium-consistency pumps are

critical components in bleaching

lines, pulp lines, and fiber

recovery lines, directly impacting

overall plant production capacity.

The KMC series pumps from Kaifeng

Pump Valve feature a single-shaft

design that eliminates the need for

external vacuum pumps (in most

cases), delivering not only

exceptional reliability and

robustness but also unparalleled

operational simplicity (the

degassing valve requires only basic

on/off logic).

SMARTSEP - A New Degassing System

Kaifeng Pump Valve was the first to

propose and practically validate a

solution for pumping

medium-consistency pulp using

single-shaft pumps. With the new

degassing system, no pressure

differential control is required to

adjust the degassing valve opening

under any operating conditions, and

there is no fiber loss (even during

low-concentration startup). The

control of the degassing valve is

extremely simple: open the valve

when the pump is running, and close

it when the pump stops. Pressure

differential control for the

degassing valve opening is only

required in extremely rare cases

(e.g., booster pump applications).

The main advantages are as follows:

• High Efficiency (>70%):

Significantly exceeding the industry

average, thereby reducing energy

consumption.

• Extremely Easy to Operate:

Virtually no fiber loss during the

degassing process (at any

concentration).

• Good Slurry Fluidization:

Effectively maintains fluidized

state of the slurry.

• No External Vacuum Pump

Required in Most Cases:

Simplifies the system, reduces

investment costs.

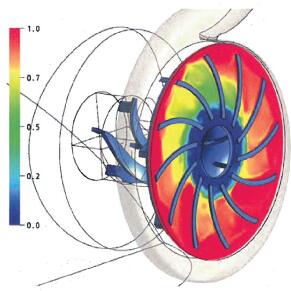

Exceptional R&D Capability

Extensive testing conducted on

in-house test platforms has

optimized the degassing process and

enhanced efficiency.

With an efficiency exceeding 70% and

minimal components, the

effectiveness of our pump technology

is significantly elevated.

The modular assembly of Kaifeng Pump

Valve’s KMC series pumps further

highlights the advantages of high

energy efficiency and simple

maintenance.

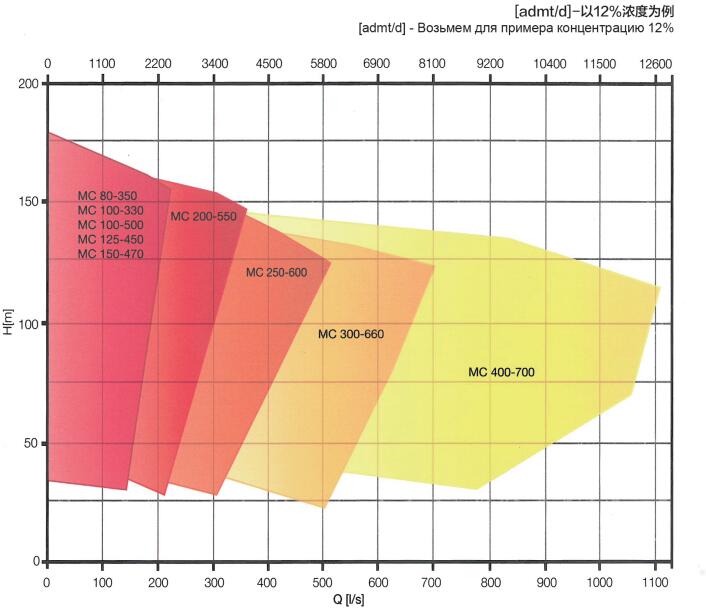

Performance Curve

|